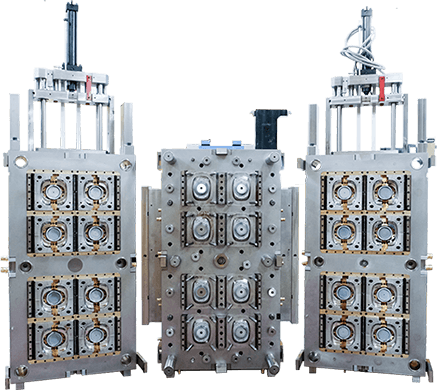

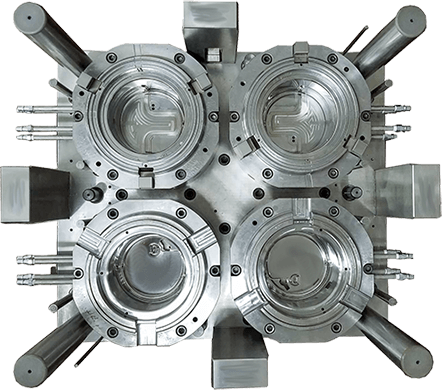

This consists of the area of the part that faces you when you look inside a mold. One simple way to describe it is that if you were to shine light on the part the projected area would be the shadow. Once you calculate the projected area you can use a general rule of 3-ton/square inch calculation for most crystalline materials to calculate the amount of force the part has generated during the molding process. Calculating Projected Area: If a projected area of a part is 635 mm (25 in) and you use 3 tons per square inch you will need to generate 75 ton per part. If you have a four-cavity mold this would require a press that has 300 tons of clamping force. By stacking another mold on top the opposing forces would cancel out the force in one direction this allows you to add 4 more cavities in the press that would normally require 600 ton press. By reducing the press size the press rates for a 600-ton would be less than a 300 ton press thus reducing the overall cost to produce the product. Molder friendly Design Tip – When you need to calculate the projected area of a part that has an irregular shape you can lay the part on a 1″gridpaper and trace the part then count the squares that are filled up. Then count the ones that are half filled divide by two and add it to the amount of full squares. Then you should have a close idea of the projected area.

Projected Area

June 29, 2017 by