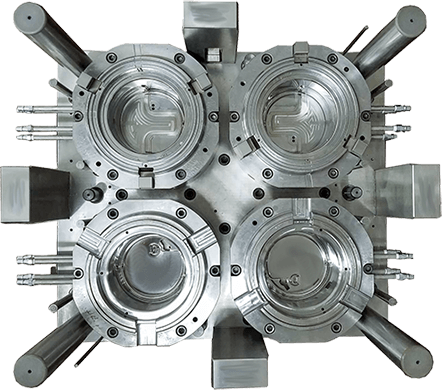

These are used to keep intersecting water lines from leaking between plates or components. 0-rings will become brittle after time and should be replaced periodically. The o-rings come in standard sizes and are very low in cost. When installed, a combination of o-ring grease and the o-ring groove construction prevents the o-rings from leaking. The process of installing o-rings in round cavity or cores in a mold base requires extra special care in to prevent shearing which leads to water leaks. This usually occurs in straight-line bores where the intersection of the connecting water line in the base comes through the cavities. A mold designer has several options in the design of the mold to prevent this potential problem. The stepped bore is the most popular way. This does add to the mold cost but in the long run will help in mold maintenance.

O-Rings

June 29, 2017 by