ATM’s quality department employs years of experience in order to bring you the product you want. Utilizing the latest zero-defect methodologies, ATM combines the use of training, equipment, and a systematic approach to ensure that all our products go out the door right the first time, every time. ATM uses modern equipment for inspection and testing. ATM can also customize submission requirements. A seasoned staff from many different industries can perform the standards: PPAP, IQ OQ PQ, and FAIR while also working with the customer to develop customized submission protocols.

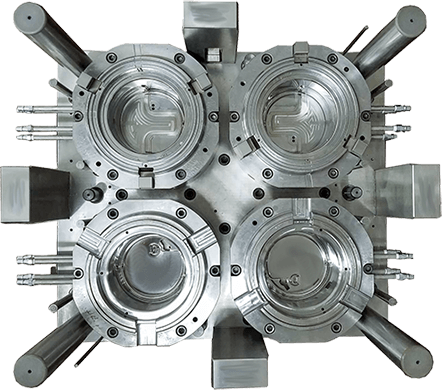

We take great pride in our work, and follow every step to ensure that our molds are built to fit your exact standards. We use a two-tiered quality control system: first, the machine operator checks all specified dimensions during the process, then the lead man re-checks those dimensions at the completion of the process, using state-of-the-art CMM and computerized optical equipment. Our gauges and measuring instruments are calibrated regularly and certified annually.

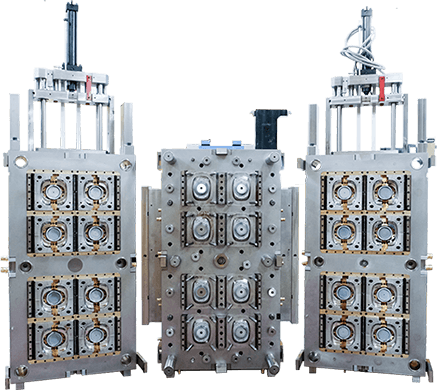

We also do process capability studies and extended pilot runs during the mold-testing/debugging phase. With every ATM mold we can supply the customer with full process data. ATM has 20 modern, high efficiency injection molding presses , a vertical rotary insert molding press and a 2-color molding press available for testing, sampling, conditioning or production.

“It is my responsibility to demonstrate what our competitors might only promise. Our dedication to excellence, our dedication to exceeding customers’ needs and our dedication to customer satisfaction is, in fact, our final product.”

Demetre Loulourgas

American Tool and Mold

We pride ourselves on the level of service we provide to each customer and our responsiveness to changing needs. The ATM project manager is the center of all communications:

- initiates quotes

- publishes reports

- reviews billing issues

- ensures accuracy and timeliness of customer commitments

“It is my responsibility to demonstrate what our competitors might only promise. Our dedication to excellence, our dedication to exceeding customers’ needs and our dedication to customer satisfaction is, in fact, our final product.”

“It is my responsibility to demonstrate what our competitors might only promise. Our dedication to excellence, our dedication to exceeding customers’ needs and our dedication to customer satisfaction is, in fact, our final product.”